IV cannula manufacturing in the USA is a niche but growing segment within the medical device sector. With rising demand for efficient infusion therapy in hospitals, clinics, and homecare settings, manufacturers are seeking ways to enter this market with compliant and high-quality IV cannulas.

This blog explains the entire IV cannula manufacturing process, regulatory requirements, machinery used, and how to successfully set up an IV cannula manufacturing unit in the USA. Whether you’re a startup or an established medical device company, this guide will help you plan and execute your manufacturing goals while ensuring FDA compliance.

What Is an IV Cannula?

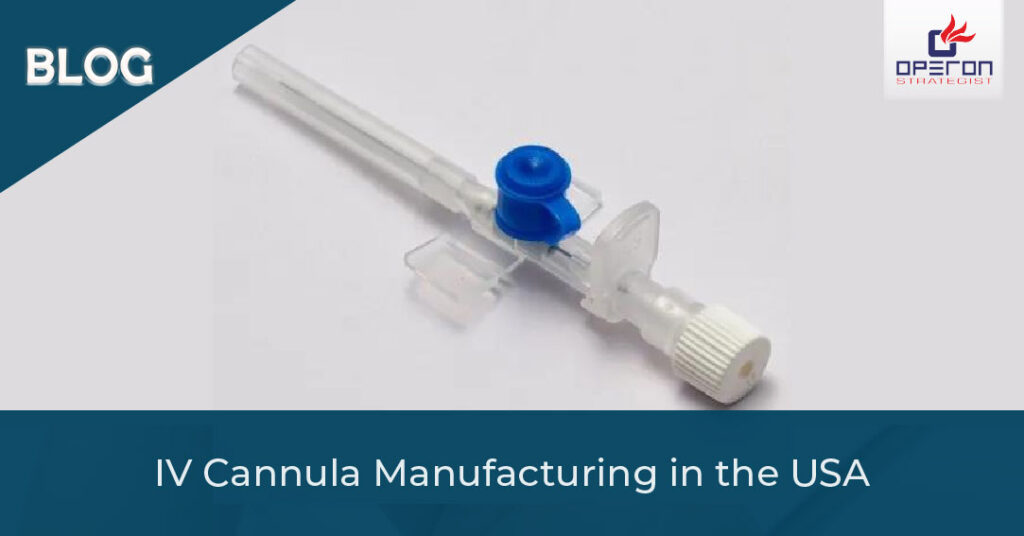

An IV (Intravenous) Cannula is a small, flexible plastic tube inserted into a patient’s vein for the administration of fluids, medications, or blood products. It is a critical single-use medical device widely used in emergency, surgical, and inpatient care.

A standard IV cannula consists of:

- Cannula or catheter (plastic tube)

- Needle (used for insertion)

- Hub (connects to IV line)

- Cap and wings (for secure placement)

Why IV Cannula Manufacturing Is in Demand

The demand for IV cannulas has grown steadily in the USA due to:

- Increase in surgeries and chronic illness treatments

- Rise in outpatient and home-based care

- Shift toward single-use sterile devices to reduce infection risks

As a result, IV cannula manufacturing presents a profitable opportunity—if done in compliance with strict FDA requirements and using quality-controlled processes.

Regulatory Requirements for IV Cannula Manufacturing in the USA

Before manufacturing or marketing IV cannulas in the USA, companies must follow regulations set by the U.S. Food and Drug Administration (FDA).

1. Device Classification

IV cannulas are Class II medical devices under 21 CFR 880.5200. This means:

- Premarket Notification [510(k)] is required

- Special controls apply

- General controls like labeling, registration, and manufacturing practices must be followed

2. FDA 510(k) Clearance

To legally market your IV cannula, you must submit a 510(k) application proving that your device is substantially equivalent to an existing legally marketed product. This includes:

- Technical specifications

- Biocompatibility data

- Sterilization validation

- Performance testing

3. Quality System Regulation (QSR)

All manufacturers must comply with 21 CFR Part 820, which covers:

- Design control

- Process validation

- CAPA (Corrective and Preventive Actions)

- Complaint handling

- Document control

4. Labeling Requirements

FDA mandates proper device labeling under 21 CFR Part 801, including:

- Intended use

- Manufacturer details

- Sterility status

- Expiry date

Manufacturing Process of IV Cannulas

The manufacturing of IV cannulas involves precise engineering, biocompatible materials, and strict sterility standards. Here’s an overview of the process:

1. Raw Material Selection

Key materials include:

- Polyurethane or Teflon for the cannula

- Stainless steel for the needle

- Polypropylene for the hub and wings

Materials must be USP Class VI certified and biocompatible.

2. Injection Molding

Plastic components like hubs, caps, and wings are made using high-precision injection molding machines. Proper mold design and cleanroom molding are essential.

3. Needle Manufacturing

Stainless steel needles are cut, beveled, and coated with silicone for smooth insertion. Automated needle grinding and lubrication systems are used.

4. Cannula Extrusion

Flexible tubes are formed using medical-grade extrusion lines, which control the cannula’s diameter and wall thickness.

5. Assembly

Cannula components are assembled using semi-automatic or fully automatic machines. The assembly process includes:

- Insertion of needle into cannula

- Attachment of hub and wings

- Leak testing and inspection

6. Sterilization

Devices are sterilized using Ethylene Oxide (EtO) or Gamma radiation, depending on material compatibility. Sterilization validation is mandatory per ISO 11135 or ISO 11137.

7. Packaging

Primary and secondary packaging is done in ISO-classified cleanrooms. Medical-grade pouches and cartons are labeled with UDI codes and barcodes for traceability.

Equipment Required for IV Cannula Manufacturing

To set up a complete IV cannula manufacturing line in the USA, you will need:

- Injection molding machine (cleanroom compliant)

- Needle beveling and grinding machine

- Cannula extrusion line

- Assembly machines (manual, semi-automatic, or fully automatic)

- Sterilizer (EtO or Gamma)

- Cleanroom setup (ISO Class 7 or 8)

- Blister packing and labeling machine

- Quality testing equipment (leak test, tensile test, sterility testing)

Facility Requirements and Cleanroom Setup

IV cannulas are sterile medical devices, so manufacturing must happen in a GMP-compliant facility with validated cleanrooms.

Key facility requirements:

- Cleanroom for molding, assembly, and packaging

- Environmental monitoring

- HEPA filtration

- Pressure differentials

- Gowning and hygiene protocols

- Separate zones for sterile and non-sterile operations

You should follow ISO 14644 and FDA’s QSR guidelines during facility planning.

Business and Market Scope in the USA

The USA has one of the largest markets for IV cannulas, driven by high healthcare spending and demand for advanced care.

Business opportunities include:

- Supplying to hospitals, clinics, and ambulatory centers

- OEM manufacturing for global brands

- Exporting to other regulated markets (EU, Canada, etc.)

However, success depends on product quality, regulatory compliance, and consistent supply chain management.

How We Can Help?

At Operon Strategist, we help startups and manufacturers set up IV cannula manufacturing units in the USA—from planning and facility design to documentation and FDA submissions.

Our services include:

- 510(k) documentation and clearance

- Facility layout and cleanroom validation

- ISO 13485 implementation

- Quality system documentation (QMS, SOPs, DHRs)

- Equipment selection guidance

We work with you to ensure your IV cannula manufacturing setup meets regulatory expectations and achieves a fast market launch.

Need help setting up your IV cannula manufacturing unit?

Contact us today for a consultation and take the first step toward entering the US medical device market with confidence.